Digital testing software for watch manufacturers: quality assurance & traceability

Many manufacturers of high-quality watches face the same challenge: maximum precision, documented quality and complete traceability of every single product. In this case study, we show how a leading watch manufacturer has digitally transformed its production by using SCIIL quality assurance and traceability software.

SCIIL success story @ IWC Schaffhausen

Together with SCIIL, IWC introduced an integrated CAQ/MES system. The initial situation:

High inspection effort during assembly and end-of-line inspection, plus the requirement for complete documentation for each serial number. Previous paper-based processes led to media disruptions and made it difficult to track complaints.

All existing processes were re-evaluated in joint project workshops and transferred to a digital overall system. The solution went live within just six months.

Quality assurance during production:

Areas of application:

![]() Final assembly (marriage of movement and case)

Final assembly (marriage of movement and case)

![]() Final inspection (function and aspect test)

Final inspection (function and aspect test)

![]() Rework and repair

Rework and repair

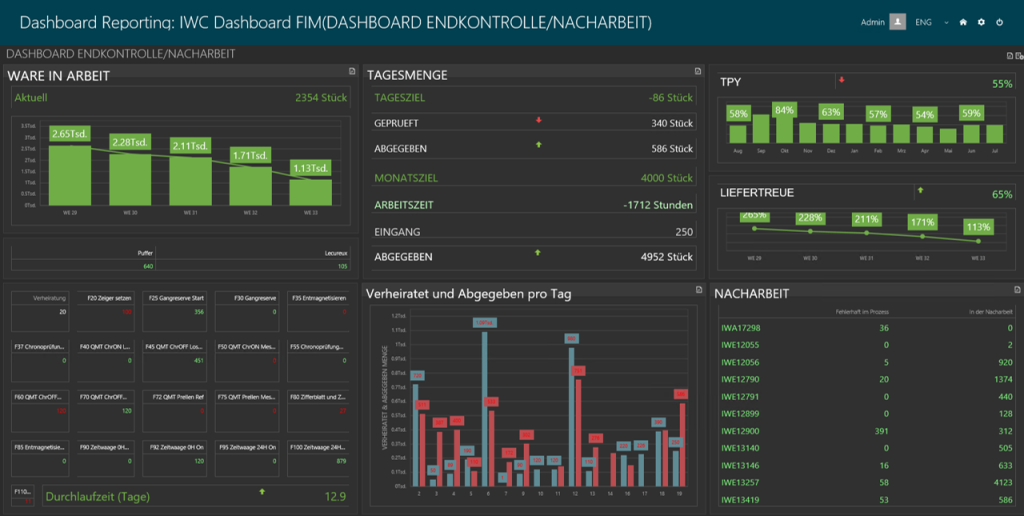

![]() Process control and data analysis

Process control and data analysis

Core functions:

![]() Serial number-based traceability of all watches and components

Serial number-based traceability of all watches and components

![]() Digital test planning and automatic reporting

Digital test planning and automatic reporting

![]() Graphical recording

Graphical recording

![]() Integration into existing systems (e.g. SAP)

Integration into existing systems (e.g. SAP)

Conclusion: Digital perfection in the art of watchmaking

Thanks to SCIIL, IWC has been able to make its quality processes more efficient, transparent and sustainable. The case study thus shows that even in a traditional manufactory, digitalization is the key to not only maintaining perfection, but to further expanding it.

The switch to SCIIL brought IWC several advantages:

- + 15 % efficiency in the final inspection

- Shorter throughput times and faster error corrections

- Improved data quality for analyses and optimizations

- Less effort thanks to automated reporting

Tracking & traceability specifically for the watch industry

Tradition meets digitalization

The watch industry is characterized by centuries-old craftsmanship and maximum precision. But it is precisely in this venerable environment that digital quality assurance and traceability software unfolds its full potential. Modern digital inspection software for watch manufacturers complements craftsmanship with automated traceability, real-time transparency and efficient processes. This gives quality assurance in watch manufacturing an immense boost – and the combination of tradition and digitalization secures the company’s leading position in global competition in the long term.

With SCIIL quality assurance and traceability software for watch production, tests were digitized, causes recorded and all data assigned to a serial number. This creates end-to-end transparency – from the individual component to the finished watch.