Automated fault detection with SCIIL AI VISION

SCIIL AI VISION is a complete software solution for automatic, AI-based visual quality inspection in industrial production environments. The system analyses high-resolution camera images in real time and reliably detects optical defects such as wrinkles, scratches, soiling, streaks or color deviations – even within tight cycle times.

The particular focus is on dynamic defects whose appearance changes depending on the material, geometry, stress or process status. This is precisely where conventional image processing and smart cameras reach their limits.

Automated quality control as an answer to the shortage of skilled workers

Manual visual inspections are labor-intensive, subjective and difficult to scale. At the same time, quality pressure is increasing, while qualified inspection personnel are becoming increasingly scarce.

SCIIL AI VISION fully automates these inspection processes. The system recognizes deviations immediately, documents them seamlessly and can interact directly with downstream processes if required – for example through line stops, rework triggers or targeted feedback to production. This allows inspection costs to be reduced, quality standards to be stabilized and personnel to be relieved in a targeted manner, regardless of the experience or daily form of individual employees.

Central AI instead of isolated smart cameras

SCIIL AI VISION deliberately relies on high-resolution standard industrial cameras in combination with a central deep learning architecture – instead of locally operating smart cameras.

The key difference:

The AI learns the defect image itself, regardless of position, orientation or fixed reference patterns. As a result, the system also recognizes dynamic defects that look different for every product and cannot be reliably detected using conventional image-to-image comparisons.

At the same time, the centralized approach enables a scalable architecture:

- AI models are trained once and then rolled out to several lines, stations or plants.

- No need to teach each individual camera locally.

- In addition, the costs of standard industrial cameras are significantly lower than those of classic smart cameras.

Smart cameras vs. SCIIL AI VISION

Smart cameras typically work with fixed reference images and local memory. They react sensitively to changes in position, variants or material changes and quickly reach their technical limits in the event of dynamic defects.

SCIIL AI VISION, on the other hand, uses AI-based deep learning with centralized data storage. The system remains robust against variations, stores all images and results permanently and enables continuous learning and data-based optimization.

Efficient training and fast commissioning

The initial AI training only requires a small amount of data. Around 100 images are enough to get started, with typical training phases lasting less than a week.

New variants or materials can be taught quickly without interfering with ongoing production operations. The central configuration allows parallel use on several lines and plants.

More than error detection: a complete vision platform

SCIIL AI VISION is not an isolated AI engine, but a database-based quality application with a user interface, administration and integrated store floor functions.

The software takes over the central configuration and control of all hardware components such as cameras, lighting and triggers. The system selects automatically via interfaces for line control and for transferring product information (article, variant, serial number):

- the right AI model

- Variant-specific test parameters

- Optimized light settings

The lighting automatically adapts to the product, material and variant, thus ensuring reproducible test results – even with frequently changing designs.

Automated pleat detection for seat assembly

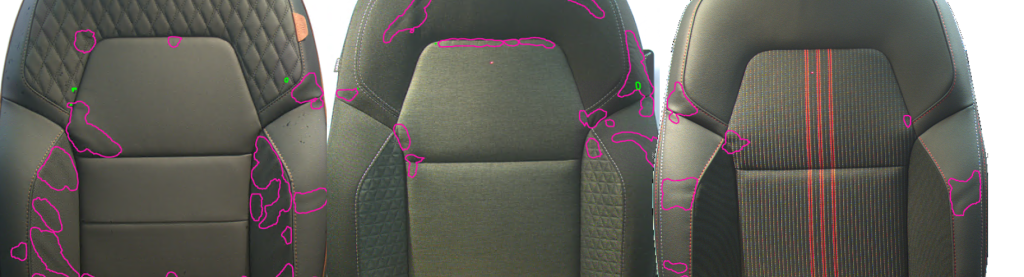

SCIIL has extensive project experience in seat production and AI-based visual quality inspection, especially wrinkle detection. SCIIL AI VISION was specifically developed for the reliable detection of dynamic wrinkles – both before and after process-critical steps such as steaming.

The system detects creases regardless of material, shape or orientation and is therefore particularly suitable for varied seating programs and changing production conditions.

Static defects such as scratches, color deviations or assembly errors can optionally be covered by existing smart camera systems (e.g. Keyence) or fully integrated into SCIIL AI VISION. All results are available centrally for traceability, heat maps, dashboards and statistical evaluations.

SCIIL VisuSteam

SCIIL VisuSteam combines AI-based wrinkle detection with the **control of steaming robots**.

The system detects creases before the process, transfers optimized parameters such as pressure, direction and time to the robot and then checks the result automatically.

Optionally, a second vision station after steaming enables an **automatic auto-learning loop** based on real production results – within the specified cycle time and with optimum utilization of the robot capacities.

SCIIL AI VISION QCX

SCIIL AI VISION QCX realizes automatic end-of-line quality control for dynamic and static defects.

The system reduces the need for manual inspections, lowers personnel costs and ensures stable quality – regardless of the experience or availability of the inspection personnel.

AI learning by the customer – without supplier dependency

An integrated AI training and relearning module enables customers to independently learn, validate and release new product variants, materials or defect images.

There is no need for fixed coding or permanent dependence on the software provider. This supports fast product launches and sustainable series production.

Traceability, analysis and prevention

All images, inspection results, defects and decisions are stored in a fully traceable manner. Based on this, SCIIL AI VISION offers dashboards, heatmaps, reports and automatic notifications in the event of conspicuous trends or defect clusters.

In this way, quality is not only checked, but actively controlled, analyzed and continuously improved.