Neuwied, Germany – With VISION, SCIIL is revolutionizing automatic defect detection. Although such systems have been around for years, the training process has been very time-consuming and has produced vast amounts of data. This is now changing with VISION.

SCIIL VISION

The automatic defect detection system

Latest News

Contact

SCIIL AGHuatai Security Building,

No. 90 on East Zhongshan

Road, Qinhuai District, Nanjing

China+86 (135) 88172747support.cn@sciil.comSCIIL USA7625 Pintail Lane,

Tuscaloosa

AL 35405

USAsupport.na@sciil.comSCIIL BALTIC UABBaltu pr. 40

48196 Kaunas

LithuaniaMonday-Friday

8:00 AM - 17:00 PM (UTC+2)+370 37 451576TEC@sciil.comSCIIL SupportMonday - Friday

8:00 AM - 5:00 PM (UTC+1)

+49 (0) 2631 99988-0support@sciil.comhttps://sciil.com/otrs/SCIIL AGMarkstraße 83

56564 Neuwied

GermanyMonday - Friday

8:00 AM - 5:00 PM (UTC+1)+49 (0) 2631 99988-0info@sciil.com

DEFECTS DETECTION with sciil vision

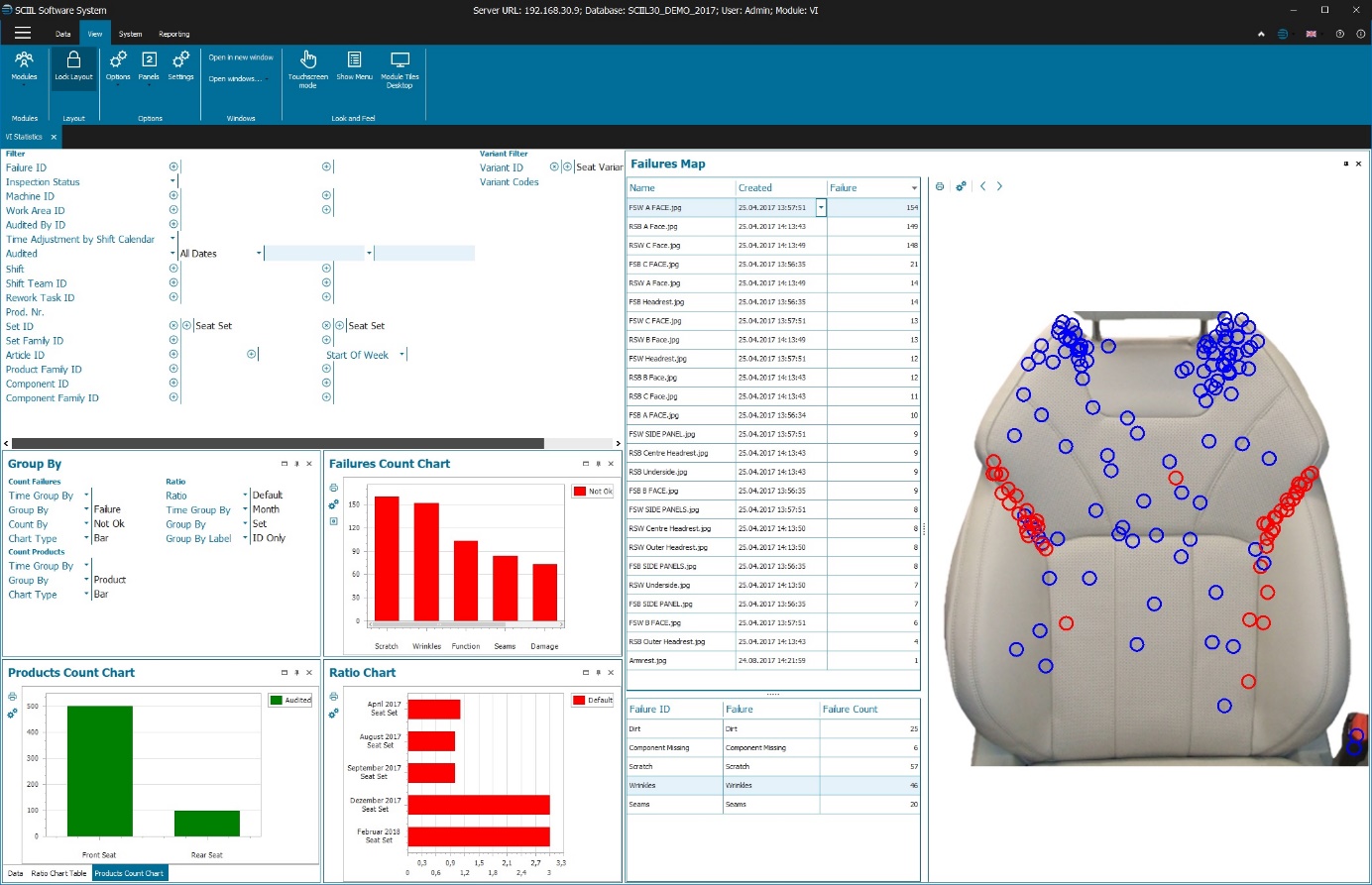

A human visual inspection of complex products takes an average of 60 seconds. Thanks to the latest AI technology, SCIIL-VISION only needs 2.2 seconds. And with an accuracy of almost 100%. But how is that possible?

Thanks to a data-driven algorithm, VISION learns from the experts. Only 20 - 25 good and bad examples are necessary for this. The recognition itself is then carried out by means of a camera with different lighting and from different perspectives. Since hundreds or thousands of images do not have to be compared, as it used to be the case with other systems , the amount of data required is kept low and the recognition doesn’t increase the cycle time. New products or models can be integrated into the neural network within the shortest time.

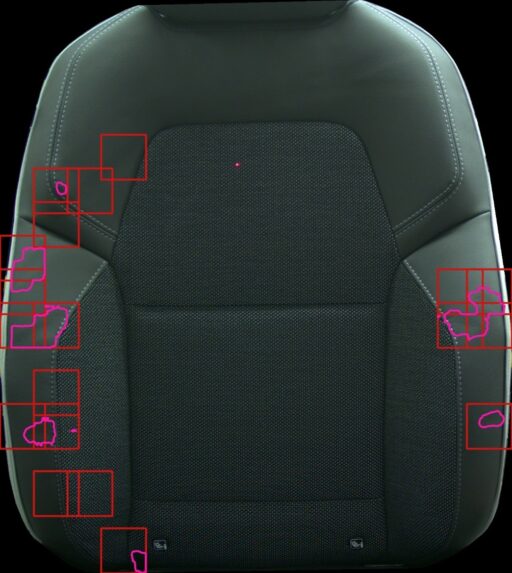

Defects are indicated on the product pictures for the following rework, the processed data can even control automated rework, the results of the rework are proved using the same technology. Online reporting and data analysis significantly contribute into the quality improvement.

With SCIIL-VISION your visions will become reality!