Automation and use of AI for pleat detection & robot ironing in seat production is challenging when different seat models with covers made of textile, vinyl or leather are processed in one line.

The methods for removing creases and the optimum control parameters for the ironing robot vary depending on the material – and this is where the challenges for quality and efficiency begin.

Quality managers report a high proportion of reworking and rising process costs as well as dependence on experienced workers and are asking for AI-based optimization of the ironing process. Although a robot is used in many systems, it irons the entire seat surface – regardless of whether there are any creases. This leads to unnecessary energy consumption, increased material wear and inefficiency. With a fixed cycle time of 53 seconds, there is also no room for manual corrections.

AI-based optimization of the ironing process in series production

The SCIIL VISION (VisuSteam) system combines camera-based AI crease detection with a direct connection to the robot and line control. It automatically recognizes the seat model and the material of the cover – leather, vinyl, textile – and selects the appropriate process parameters.

The result is a self-learning closed-loop mechanism that automatically adjusts control parameters and thus improves from cycle to cycle.

Line control provides data on the seat: unique serial number, model, variant, cover

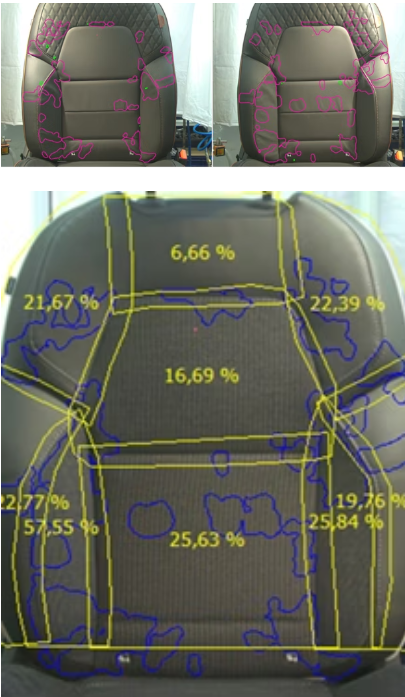

Cameras capture images under two light settings

AI recognizes and classifies wrinkles according to position, direction and severity

System assigns ironing zones and parameters (zone priority, pressure, cycles, etc.)

Robot irons according to zone-specific instructions

AI checks the result again after ironing

Parameters are automatically adjusted as required (self-learning control loop)

This provides production and quality managers with a solution that not only automates, but also continuously optimizes – ideal for lines with high cycle loads and constant quality requirements.

Implementation and framework conditions

The customer produces seats with textile, vinyl or leather covers in numerous model variants with different shapes, designs and seam patterns. The line works with a fixed cycle time of 53 seconds, with only 48 seconds effectively available for the actual ironing process.

The central task: reliably detect creases, automatically apply optimum ironing parameters depending on the material and zone and continuously and automatically optimize the entire process using AI crease detection & control of ironing robots.

Verification test after project completion:

Results of a one-hour test run with 63 seats:

- ~99% of wrinkles are correctly detected

- <6% false detections (false positives)

- Only 0.28 – 1.58 % of the surfaces were ironed without creases

In addition to these key figures, the plant benefits from less manual intervention, reduced reworking and better material protection – especially with sensitive covers such as leather.

Conclusion

The system takes the pressure off production and quality teams, standardizes results and makes processes scalable. This is a real competitive advantage for lines with high throughput and clear cycle times.

- Lower quality costs (CoPQ)

- Minimized “free ironing”

- Completetraceability

- Standardized and reproducible quality

- Simple rollout to other production lines