SCIIL ePYV does not replace poka-yoke devices or methods, but digitizes their planning, execution, monitoring and documentation.

Case study: Digital poka-yoke verification replaces paper-based checks and creates measurable benefits.

At a Customer Experts Workshop in 2017, key users of the SCIIL system expressed a clear desire for an IT-supported solution. The aim was to digitize the planning, execution, monitoring and documentation of poka-yoke inspections, as paper-based shift books, manual overviews and time-consuming documentation were increasingly no longer meeting the requirements of series production.

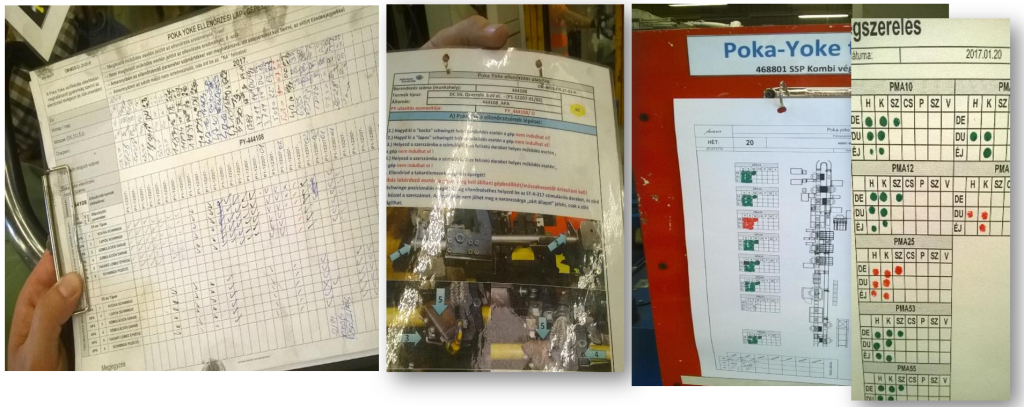

Initial situation: Paper-based poka-yoke verification

Poka-yoke verification was paper-based using shift books, printed inspection instructions and weekly overviews. At the same time, manually created reports and overviews existed, meaning that a centralized and up-to-date view of the status of the poka-yoke tests on a PY dashboard was not possible at all times.

Paper-based poka-yoke verification had several key disadvantages:

- No timely monitoring of implementation

- No immediate reaction

- Documentation through filing

- Mauelle reporting

- No “lessons learned”

- Laborious OEM and customer audits

From the experts’ point of view, it was therefore clear that the paper-based control was ineffective and unreliable. As a result, there was a need for an electronic solution to manage and monitor poka-yoke activities.

Requirements from the customer workshop:

Specific requirements for software to monitor poka-yoke activities were defined during a customer workshop:

- Mobile andsimple input

- Real-time control at line level

- Automated workflows and notifications

- PY Dashboards

Based on these requirements, SCIIL developed the ePYV – Poka Yoke Verification module.

Solution: Digital poka-yoke verification with SCIIL ePYV

Reduction of ongoing expenses through digitization

Assessment basis: Automotive plant with 2-shift operation, around 100 poka-yoke tests per production day and around 260 production days per year. This scenario corresponds to the typical use of poka-yoke tests in series production and forms the basis for the following benefit analysis.

Measurement method (customer-based): Time measurements before and after implementation for the entire accompanying process: planning of checks, maintenance and distribution of instructions, manual documentation, data follow-up for overviews and boards as well as the provision of evidence for internal and external audits.

Result: Thanks to digital poka-yoke verification, the customer was able to permanently reduce ongoing expenses. The measured reduction in workload is around 200 hours per year and is divided between production, quality and back office.

This time saving results from the elimination of paper-based activities, the centralized digital planning and maintenance of poka-yoke checks, automated status tracking and the immediate availability of all evidence in the system. Instead of manual coordination and rework, clearly structured, digital processes are created.

Business case & decision of the customer:

Based on these results, the global management approved the rollout of SCIIL PYV to 73 plants worldwide.